Housing gives man a sense of mental security, protection from adverse weather conditions and other intending dangers, it boosts social well-being and helps promote self-esteem which in turn makes him comfortable and proactive to achieve other needs and set goals in life.

A nation progresses when its citizens are provided with affordable housing as most of the labour force becomes more productive when they are adequately housed thus boosting the labour output and general development of the nation.

It is against this background that we must recognize the importance of the construction industry in the socio-economic development of a nation. Many times, the national progress, technological and political advancement of most countries are reflected by the pedigree of their construction industry and the feats achieved over time.

The Nigerian building and construction sector should be no exception and as such been described by Okigbo (1982) and Mogbo (2001) as being ‘important and ‘crucial’ to her economy. Building materials were identified by Abiola (2000) as one of the principal factors affecting the performance of the building construction sector. With an estimated population growth rate of about 2.5%, it is believed that 1.5 million new homes would be required annually between 2012 and 2025 (Hogarth et al, 2015).

The magnitude of the housing deficit in Nigeria is such that government alone cannot cope with its mitigation. As a result, public-private partnerships are gaining ground as an important route for mitigating the housing deficit in Nigeria. (Ibem and Aduwo, 2012).

NBRRI AND ITS ROLE IN TACKLING HOUSING DEFICIT IN NIGERIA

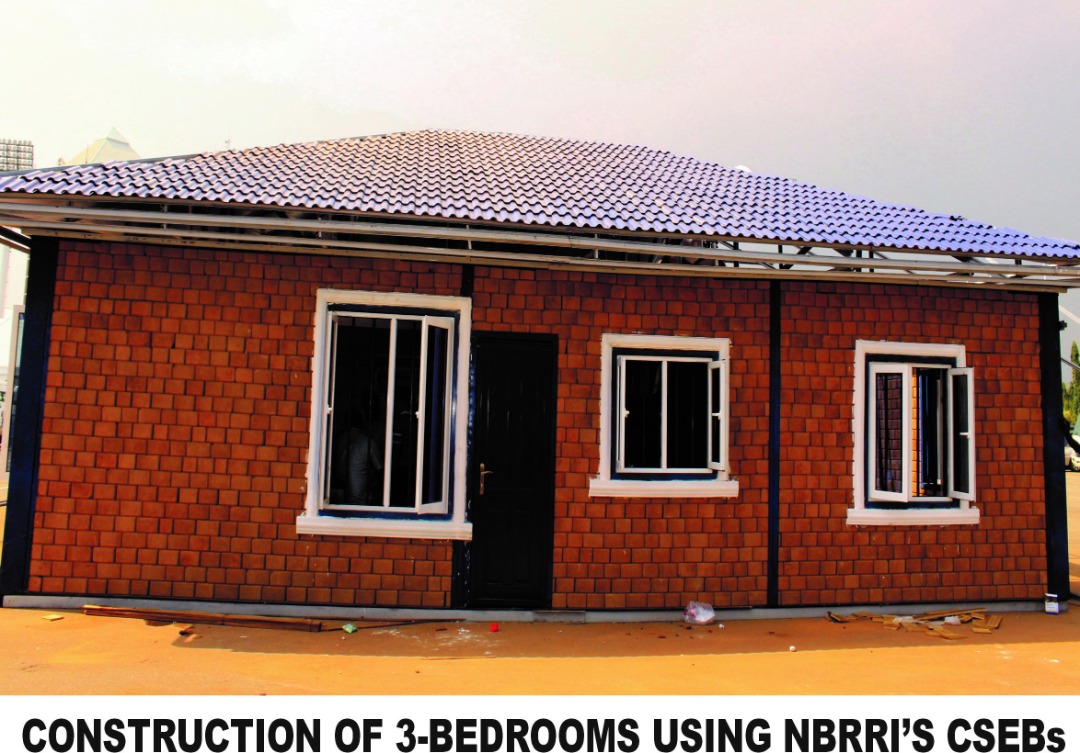

Right from inception, the Nigerian Building and Road Research Institute has placed a priority on the development of alternative building materials which are locally available and the Compressed Stabilized Earth Blocks (CSEBs) is one of such innovations. The use of earth construction materials, techniques, and equipment are environmentally friendly and provide both comfort and affordability. This CSEB is a primary product from the natural clay in our environment referred to as laterite.

CLAY: Is the oldest natural building materials. It consists of a mixture of clay, sand, and dust. It may also contain coarser particles (gravel) or organic material. The most common way to use clay for construction is in the form of clay bricks or in the form of ramming. In addition, it presents the filling of half-timbered construction and wood-framed construction or as a clay plaster.

COMPRESSED STABILISED EARTH BLOCKS (CSEB): Compressed Stabilized Earth Blocks (CSEB) are basically made from local materials (Laterite) which is readily available in various parts of the country. The blocks are interlocking blocks and do not require plaster, paint and cement mortar in bonding the blocks during construction, thereby reducing building cost.

The use of CSEBs as a walling material is a sustainable construction technique as it is affordable, durable and accessible. When compared with alternatives such as fired brick and sandcrete blocks, CSEBs offers lower construction costs at comparable quality and is suitable for a wide range of environments, and dramatically reduces the impact on the environment.

Other advantages are that it ensures the use of locally available construction materials thereby reducing transportation costs; ensures the availability of quality and affordable housing for a wider population; creates job opportunities as the technology requires semi-skilled labour which are easily transferable to locals; it generates local revenue as the materials and labour are sourced locally, and it is more energy-efficient considering its lower embodied energy. CSEBs have very good insulation and thermal properties and also possess the ability to absorb atmospheric moisture resulting in a healthier environment for the occupants.

Based on the cost analysis carried out by NBRRI on the blocks, it was found that NBRRI Compressed Stabilized Blocks are cheaper alternatives to Sandcrete blocks, giving a 20% reduction in the total building cost. From the Bill of quantities computed and using CSEBs in the construction of 1, 2 and 3 bedrooms a percentage cost reduction of 22%, 20% and 21% were obtained respectively compared to sandcrete blocks. These are interlocking walling units made from 90% earth (laterite) and 10% cement and water. The blocks are dry-stacked, with each block interlocking into adjacent blocks to create a strong monolithic wall. The blocks are also laid to finish with a pleasant rustic-red colour of earth, obviating the need for plastering or painting.

BENEFITS OF THE NBRRI CSEB

* Clay which is the main constituents are locally and abundantly available

* Less use of cement which is an expensive material for building

* Blocks are dry-stacked, interlocking into each, into a monolithic structure

* Ease of use with little or no supervision

* Ability for on-site production, curing and usage

APPLICATION OF NBRRI TECHNOLOGY

The CSEB have been deployed in all the 6 geo-political zones of Nigeria, as constituency projects. Examples are skills acquisition centres, classrooms, assembly halls, healthcare centres, etc. A comparative analysis was made for the walling materials in a 2 bedroom and 3 bedrooms respectively. A huge percentage difference was recorded.

SUMMARY

Three-bedroom Conventional NBRRI Technology (1). Internal and external walls 1,225,000.00 979,650.00. (2) finishes 536,700.00. Total 1, 761700 979,650 percentage difference 44.3%

Two-bedroom Conventional NBRRI Technology (1). Internal and external walls 1,155,000.00 882,000.00. (2) finishes 566,300.00. Total 1,721300 882,000 percentage difference 48.7%.

It is to note that these blocks are compressed with a force of 5N/mm² using hydraulic or manually operated machines. This makes them dense and suitable as external and internal walling material.

NBRRI COMPACT INTERLOCKING BLOCK MAKING MACHINE

- FEATURES:

- Dimension (1100*600*1500) mm

- Retractable tricycle suspension system

- A 6.5hp water cooled diesel engine

- Speed of 2800 rpm

- 1500 blocks / day

- Portable

- SIGNIFICANCE/BENEFITS:

- Reduction of machine production cost by trimming-off excess capacities/components

- Reduction of operational production cost by adopting lower fuel and oil utilizing mechanical systems

- Ensuring machine portability with minimal manual ease and at a comparative lower cost

- Reduction of production down time by utilizing locally available serviceable standard

parts

- Reduction of production cycle by fully automating the actuation mechanisms

- Adopting tropical weather friendly systems

- Closing the overall national CSEB’s production demand gap

- Creation of a value chain in the utilization of local raw materials and methods

- Promotion of inventions and innovations in the Institute’s STI policy

- Fast tracking the Commercialization of the Institute’s interlocking blocks walling

technology through Prototyping

- Enhancing PPP strategy in Building sub-sector of the construction industry.

- APPLICATION:

- Small and Medium scale housing production

- PPP projects

- Energy demand reduction-based projects

- Remote sites

CONCLUSION/RECOMMENDATIONS

In line with this, it is imperative to recognize the fact that the cost reduces when it is to be deployed in multitudes.

- Restructure and adequately fund the Nigerian Building and Road Research Institute (NBRRI) to perform its statutory role.

- Grant fiscal incentives to small and medium scale local manufacturers of locally sourced building materials.

- Reduce the dependency on imported construction materials and technologies. 4. Encourage the use of laterite/clay (CSEB) as a walling for mass housing employment and wealth generation.

4. The use of CSBs in mass housing delivery programmes can be promoted through effective public enlightenment programmes targeted at all stakeholders